Ryan Wilson - Waikato

How teat spray tech transformed Ryan Wilson's milking routine

By fully automating his teat spray routine, from mixing to application, Ryan is confident his cows are getting consistent, accurate coverage after every milking without any manual labour from his team.

Ryan Wilson manages 650 cows and a team of five on his family’s farm in the Matamata-Piako region. The Wilson’s have a rich heritage on the farm that spans over 116 years, where the family own and operate a dairy and beef farm, as well as a sand supply and green waste business – Wilson Sand.

In late 2024, Ryan Wilson was among the first farmers to trial GEA’s new iSPRAY-VISION walkover teat sprayer. To ensure the technology performed reliably across different conditions and set ups, the walkover was rigorously tested in real farm environments.

Designed for both herringbone and rotary sheds, the iSPRAY-VISION walkover teat sprayer was designed and collaborated with AgriAI, representing a major advancement in walkover technology. Equipped with AI-driven camera technology, it delivers real-time udder tracking and timed sequential spraying. This provides thorough coverage of both the front and back of the teats as cows walks over the unit - regardless of their speed or how closely they follow one another.

Prior to installing the iSPRAY-VISION, Ryan was using a different walkover system that wasn’t delivering the results he had hoped for. Within three months of replacing the old walkover for GEA’s unit, Ryan noticed significant improvements in his herd’s udder health. Typically, he would expect his somatic cell count (SCC) to rise over summer, but it has remained steady between 150,000 – 180,000 through November, December and January. Over the same period, mastitis cases in his herd also reduced.

One of the biggest differences Ryan noticed compared to his previous walkover was the shift from two spray nozzles to four. The crossfire spray pattern, rather than a lateral one, ensures more even coverage around all four quarters.

An unexpected but welcomed benefit, Ryan says, is how the walkover slows cows down before the drafting gate, improving drafting reliability and efficiency.

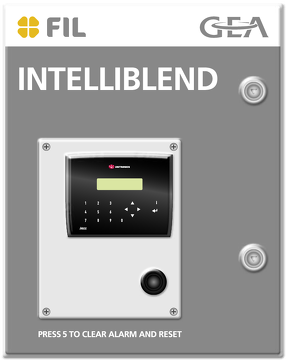

Looking to eliminate hand mixing teat spray, Ryan also installed FIL’s Intelliblend teat spray mixer and delivery system. Working in tandem with the walkover, it automatically mixes and pumps Iodoshield Active teat spray and Active Teat Conditioner emollient at pre-programmed mix rates. The mix rates can easily be adjusted on the Intelliblend unit throughout the season depending on emollient requirements.

By fully automating his teat spray routine, from mixing to application, Ryan is confident his cows are getting consistent, accurate coverage after every milking, without any manual intervention from his team.

When it comes to service, Ryan says the installation process with GEA, AgriAI and FIL was smooth and hassle-free. “The installation process was easy, it didn’t feel like a chore,” he says. “Tania at FIL has also been great in helping me select the right teat spray product for my farm”.