Travis & Lisa Parry - Northland

Teat spray automation brings big benefits on Northland farm

Using an automatic teat spray mixing system has given Northland farmer Travis Parry not only ‘peace of mind’ but has demonstrated that even smaller scale farms will see plenty of big benefits.

Using an automatic teat spray mixing system has given Northland farmer Travis Parry not only ‘peace of mind’ but has demonstrated that even smaller scale farms will see plenty of big benefits.

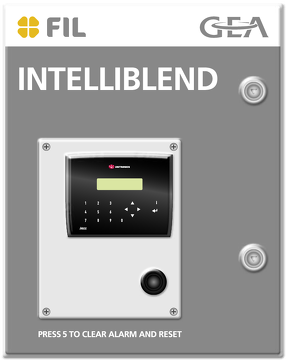

Travis and his family are 50/50 sharemilking on a 110-hectare (ha) farm ten minutes outside of Whangarei and had FIL’s Intelliblend teat spray unit installed at the beginning of the year. They were the lucky winners of the Farm Source Intelliblend giveaway in 2021.

The locally made system, designed by FIL, is being used up and down the country, most predominately in larger farms. However, with a herd of 320 cows, Travis says the system is just as effective on smaller to medium sized farms. “Large scale or small scale, the benefits are all the same,” he says. “We still have the same challenges as bigger farms, so by using this system, we’ll be seeing the same benefits.”

Travis and his wife Lisa, alongside a couple of farm workers have been at their current farm for 9 seasons. Travis is a lifelong dairy farmer and now has a bundle of three school-aged children tagging alongside him and Lisa on the farm.

He’s been a happy FIL customer for several years, using a variety of FIL products and says using the automatic teat spray system has certainly given him peace of mind as well as giving him instant benefits.

“It has made things so much easier, as you don’t really need to think about it,” he says. The Intelliblend system is set up to accurately mix “ready-to-use” teat spray at set ratios, eliminating product wastage and inconsistencies found with manual mixing. The ready to use (RTU) teat spray is then delivered to hand-held spray guns on droppers in the pit.

“There’s definitely a daily time saving benefit and we’ve been able to eliminate mistakes too,” says Travis, adding that “there’s no more remembering to fill up this or that, or what the mixing rates are.”

Not having to leave the pit to refill or mix has been one of the biggest benefits for Travis and his team.

“You’d be halfway through milking and then need to leave the pit to go mix the spray up. Now, I don’t even need to think about the teat spray,” he says.

Travis says their SCC has been reasonable so it’s hard to say just yet if there are any improvements to be seen there, having only been using the new system for 5 months.

“However, through the spring is when we may start to notice any improvements,” he adds. “Long term, I’m sure we will see cost savings because of that too.”

One of the features of the Intelliblend is an audible alarm when teat spray and drum contents are running low and again when the drum is empty.

Although Travis has not yet experienced that specific feature, he has been alerted to a water pipe blockage by the system, which he was able to manage easily and quickly.

The system is also easy to program depending on environmental changes. When conditions change, or a deterioration in teat condition is detected, the system’s settings can be altered to counter changing patterns of teat condition.

The transition to the Intelliblend system was extremely straight forward says Travis. FIL’s local Area Manager Brian Salvigny set up the system on the farm and has supported Travis along the way.

“We had it put in which took a couple of hours and it has worked well from the get-go, it’s been awesome,” says Travis.

“Brian is only a phone call away if we need anything or need help with anything, he’s awesome,” he adds.

Since the Intelliblend system was set up, Brian has been back on farm to check up on things a couple of times. “The support is always welcome and helpful,” says Travis.

For more information on the Intelliblend, get in touch with your local FIL Area Manager.